The more I think about it, the more amazed I am at the way the launch of the Apple Watch has gone down.

It was, in many ways, a botched launch. Consumer interest and demand proved to be very high, but the research suggests that Apple was able to process and fulfill only about 22 percent of the initial orders. Everything else was delayed.

This comes on top of the fact that Apple introduced a strange new online-only ordering process for the Watch. There’s no more in-store impulse buying. No magic moment in the store where you say “I have to have that” and then lay down the plastic. No immediate gratification. Instead you wait (and wait) for the notification to finally arrive from Apple saying your product is about to ship.

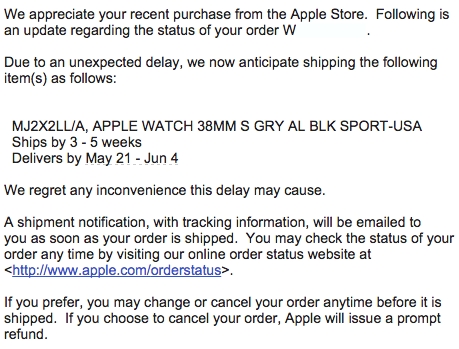

Many people who ordered on Day 1 (including one of my coworkers) have now received two delay notices from Apple. Some, however, have also received a note saying that the estimated ship date has been moved up. Regardless, most people are having to wait anywhere from a few weeks to a few months, depending on the Watch model they ordered.

The result, I think, is that many people’s first experience with the Apple Watch — and for some, their first experience with smartwatches, full stop — is kind of a bummer.

Is this really the way Apple wanted to introduce people to its first entry to a whole new category of personal technology? I’ll spare you the “planned scarcity” theories, because I doubt they apply here, but it does seem odd that Apple messed this up given all the time it had to prepare for the launch.

Did Apple underestimate the level of demand for the Watch at launch? I doubt it. The company reportedly aims to sell 20 million of the devices in 2015, and we’re already well into the year. If the company anticipated such strong demand for the whole year, how could it have underestimated demand at launch?

“When you have a new product in a new category, there often isn’t industry or benchmarking data available to help estimate the demand,” FusionOps CEO Gary Meyers pointed out. FusionOps makes a cloud-based intelligence platform for managing product launches, including the supply chain.

OK, so maybe underestimating demand could be part of it. But yesterday we heard reports that the delay was related to faulty haptic feedback components — the little bits inside the Watch that buzz your wrist. Apparently the haptic feedback engines (or “Taptic” engines, in Applespeak) produced by one of two Apple suppliers, AAC Technologies Holdings, had to be discarded, so that most of the supply had to be produced by the other supplier.

I understand that these parts suppliers build lots of parts for lots of OEMs, and that they have to set up and tear down manufacturing processes on tight timeframes. But it still seems incredible that the faulty parts would have been discovered so close to launch that it would result in such a serious shortage.

Meyers shed a more positive light on this too: At least Apple arranged to have two suppliers in advance, he said. While Meyers acknowledged that dual sourcing is a common practice, he stressed that it’s less common for OEMs to dual-source brand new inventions like Apple’s Taptic thingy.

I remain skeptical. I don’t think all the facts have come out about what exactly went wrong with the launch. Indeed, the first thing Meyers told me when I spoke to him was that it still isn’t at all clear that the Taptic engine problems were the sole reason for the distribution delays. There may have been other problems we don’t know about yet.

All the facts will surface someday, and it’ll be a good story. There’s a good chance we’ll read all about it on the little screens of our Apple Watches.

VentureBeat's mission is to be a digital town square for technical decision-makers to gain knowledge about transformative enterprise technology and transact. Learn More