Semiconductors have become a business of astounding numbers. Chip makers can put a billion transistors on a chip. Mobile and computing devices are shipping at a rate of almost 2 billion units a year now. And if chip manufacturing hits a wall, electronics companies could lose billions upon billions of dollars.

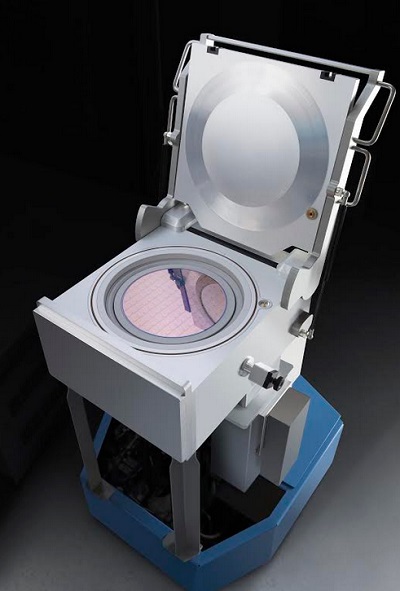

That’s why Applied Materials believes it has an important breakthrough today with the launch of its Endura Volta CVD Cobalt chip manufacturing machine. Applied calls it the most important change in materials for microchip wiring in 15 years.

Santa Clara, Calif.-based Applied Materials is the world’s largest chip equipment manufacturer, with $7.5 billion in sales last year. Without Applied Materials machines going into factories of chip makers like Intel, the electronics world wouldn’t function.

The new Applied Endura Volta CVD Cobalt system can be used to make chips with features that are so small there are just 28 nanometers between circuits. A nanometer is a billionth of a meter. Applied says its tool is the only one capable of encapsulating copper wiring in logic chips. Copper is very good at conducting electrons through a chip, but it can cause a lot of trouble if it isn’t properly contained within a chip that is made of semiconductor materials.

AI Weekly

The must-read newsletter for AI and Big Data industry written by Khari Johnson, Kyle Wiggers, and Seth Colaner.

Included with VentureBeat Insider and VentureBeat VIP memberships.

Applied created two applications, a “conformal cobalt liner” and a “selective cobalt capping layer.” These enclose the copper wires, improving reliability by at least 10 times. The use of cobalt as a metal encapsulator is the most significant change in 15 years. That will help preserve Moore’s Law, the postulation by Intel Chairman Emeritus Gordon Moore that the number of transistors, or on-off switches, that can be built on a chip doubles every couple of years.

“The reliability and performance of the wiring that connects the billions of transistors in a chip is critical to achieve high yields for device manufacturers. As wire dimensions shrink to keep pace with Moore’s Law, interconnects are more prone to killer voids and electromigration failures,” said Randhir Thakur, executive vice president and general manager of the Silicon Systems Group at Applied Materials. “The Endura Volta system builds on Applied’s precision materials engineering leadership by delivering CVD-based cobalt liner and selective cobalt capping films that overcome these yield-limiting issues to enable our customers to scale copper interconnects to beyond the 28 nanometer node.”

The new system adds two steps to the process of making chips. First, the machine deposits a layer of thin cobalt as a liner around the copper wiring. This helps improve the performance and quality yield of the device. The second step involves depositing cobalt selectively. The result is an 80 times improvement in device reliability.

“Applied’s unique CVD cobalt processes represent an innovative materials-enabled scaling solution,” said Sundar Ramamurthy, vice president and general manager of Metal Deposition Products at Applied Materials. “It is deeply satisfying that these materials and process innovations in development for almost a decade are now being adopted by our customers for their high-performance mobile and server chips.”

VentureBeat's mission is to be a digital town square for technical decision-makers to gain knowledge about transformative enterprise technology and transact. Learn More