QuantumFilm could usher in a new age of high-quality, thin, inexpensive digital cameras and camera films.

[aditude-amp id="flyingcarpet" targeting='{"env":"staging","page_type":"article","post_id":169003,"post_type":"story","post_chan":"none","tags":null,"ai":false,"category":"none","all_categories":"business,","session":"A"}']Based on a new kind of image sensor technology from chip startup InVisage Technologies, QuantumFilm can deliver mobile phone camera images that are four times sharper than today’s cameras, with twice the dynamic range, or the ability to have both dark and light features in the same picture.

AI Weekly

The must-read newsletter for AI and Big Data industry written by Khari Johnson, Kyle Wiggers, and Seth Colaner.

Included with VentureBeat Insider and VentureBeat VIP memberships.

Unveiled today at DEMO, QuantumFilm uses a new kind of custom-designed material, dubbed a quantum dot, that can replace a typical silicon image sensor. Today’s imaging chips use complementary metal oxide semiconductor (CMOS, a standard process in chip factories). They capture only about 25 percent of the light that hits the surface of the silicon.

The first samples of QuantumFilm camera chips will be available in the fourth quarter, and products using them will likely launch next year. InVisage developed QuantumFilm based on the research of its chief technology officer, Ted Sargent. He worked on the technology for several years at the University of Toronto. Then he secured the rights to the technology and founded InVisage Technologies in October, 2006.

Some of the ideas in this space come from the solar market, where the makers of solar cells are starting to move away from silicon solar cells because they’re not as efficient at capturing light. The company recruited veterans from the CMOS image sensor market, including chief executive Jess Lee, a former executive at image sensor maker Omnivision.

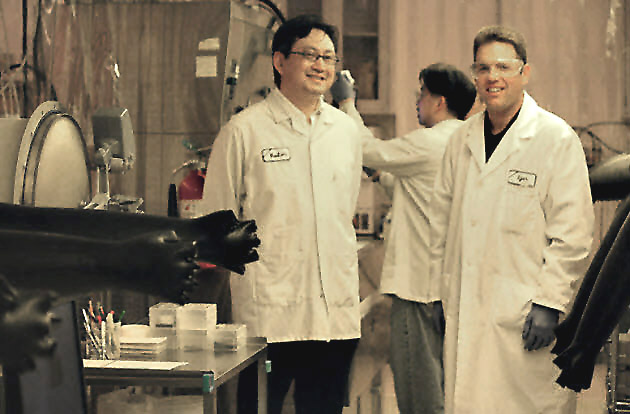

Lee (pictured at top, left, with Michael Hepp, director of marketing, right) said in an interview that it took about three years to engineer the quantum dot material, which is a byproduct of research into nanotechnology. The material was engineered from the outset to be good at light capture, the essential task of a camera. The material is “tuned” so that, when hit with light, it emits a different color. The quantum dots sit in a suspension and can be splashed onto anything. I visited their lab last week and watched the sputtering machine in action (pictured below; thanks to Clark Thomas for cleaning up the photo).

[aditude-amp id="medium1" targeting='{"env":"staging","page_type":"article","post_id":169003,"post_type":"story","post_chan":"none","tags":null,"ai":false,"category":"none","all_categories":"business,","session":"A"}']

By coming up with a new material, Menlo Park, Calif.-based InVisage may very well be able to upset the conventional wisdom that it is just too expensive to create a new semiconductor startup to compete with giants. InVisage will compete with a number of big chip makers, including Omnivision, Aptina, Samsung and Sony. The irony is that those chip makers created CMOS image sensors that killed off older chips dubbed charge-coupled devices.

Those companies are having a harder and harder time coming up with better image sensors, Lee said, because silicon has hit a technological barrier. Tetsuo Omori, an analyst at Techno Systems Research, estimates that the image sensor companies spend about $1 billion for each new generation of sensor technology, and each time they get a single-digit percentage increase in performance. A four-fold improvement is unheard of, and so Omori thinks QuantumFilm will change the competitive landscape in the image sensor market, which had $5 billion in revenue in 2009.

All cameras could benefit from QuantumFilm, but the biggest benefit will be in camera phones where the demand is greatest for small, high-performance image sensors. Eventually, QuantumFilm could be used in security cameras, car cameras, and military applications such as night-vision goggles.

InVisage has 30 employees and has raised more than $30 million from RockPort Capital, Charles River Ventures, InterWest Partners and OnPoint Technologies. Its technology is protected by 21 patents and patents pending. Lee said the company will likely raise a third round of funding as it moves into mass production next year.

[aditude-amp id="medium2" targeting='{"env":"staging","page_type":"article","post_id":169003,"post_type":"story","post_chan":"none","tags":null,"ai":false,"category":"none","all_categories":"business,","session":"A"}']

http://c.brightcove.com/services/viewer/federated_f8/980795693

VentureBeat's mission is to be a digital town square for technical decision-makers to gain knowledge about transformative enterprise technology and transact. Learn More