Ledbetter said that his team was able to rapidly iterate on the design working in the Model Shop. They created more than 200 different controller designs using the prototyping machines. The lab has three 3D printers to churn out the prototypes. Jesus can get a design printed overnight and send them over to the designers for evaluation quickly. Jesus was delivering six of those a day in time for morning reviews.

“We had four or five directions we were interested in and tested them,” Ledbetter said. “We printed them and assembled them. We put them together and then evaluated performance.”

Navin Kumar, a senior product manager at Microsoft, said in a demo of the Xbox One Wireless controller that there were more than 40 enhancements to the Xbox 360 controller for the new generation. Those changes are designed to “maximize gaming realism.” The aim is to keep you immersed in the action longer. The device includes “impulse triggers,” better thumbsticks, and a redesigned D-pad. The latter was a sore point for gamers because it was easy to mistakenly hit the wrong part of the pad while playing a game. The device is also designed for more precision and control.

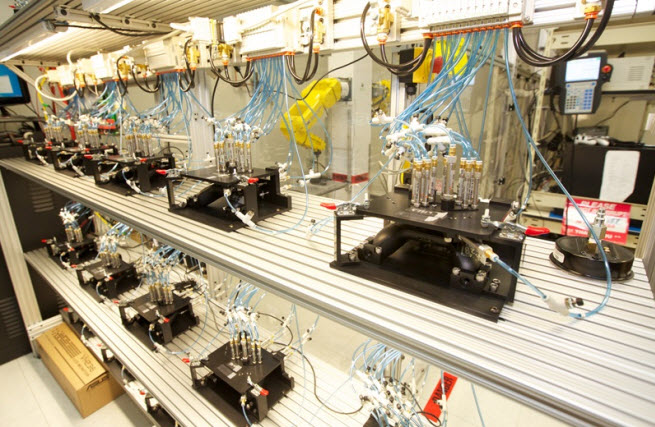

Bob Brown, the director of test for the controllers and other accessories, said that each controller has its buttons tested more than 2 million times over the course of two days. You can see that simulated above by the machine that actually push the buttons. This testing approximates a lifetime of seven to 10 years. That enables Brown to predict the lifetime of the controller and its failure rates. He will continue to test the controller failure rates even after the console ships so that the quality team can monitor consistency of production.

“We do everything here from cradle to grave,” said Brown, who once tested the parts on F-16 fighter jets. “We have software developers in here. We generate our own tools because you can’t find off-the-shelf tools to test controllers.” There are wireless experts, mechanical engineers, and other experts.

“The tests hit every button and we record what happens,” Brown said. “If one fails at 750,000 pushes, we record that with a camera that takes 250,000 frames per second.”

Early on, the team had to change the D-pad to get around a reliability problem. But the overall design has turned out to be sound, Brown said.

When a device fails, Brown hands it over to a failure analysis team to figure out what went wrong. The camera images come in useful for that analysis. Brown can change the pattern of tests via a computer dashboard. Brown also has a machine [below] that simulates shaking. And he showed off a slow-motion video that captures what happens to a controller when it is dropped on the ground. The video has a breakaway plastic part that pops off during the fall, allowing the team to see what happens inside when it falls.

Now with all of the talk of reliability, it’s hard to avoid the issue of the Red Rings of Death, the error message that resulted when the Xbox 360 failed, mostly due to overheating problems, in the last generation. Microsoft fixed that problem with a chip redesign that went into effect during mid-cycle, but prior to that, large percentages of its consoles failed, and Microsoft had to take an embarrassing $1.1 billion write-off to replace broken machines.

Brown said he tested the controller with consoles all of the time. Asked about what Microsoft would do to avoid the Red Ring of Death problem from the Xbox 360, Brown said that console testing wasn’t his department. I’m sure that Microsoft will say it has that figured out, but it wasn’t part of its messaging on Tuesday.

VentureBeat's mission is to be a digital town square for technical decision-makers to gain knowledge about transformative enterprise technology and transact. Learn More