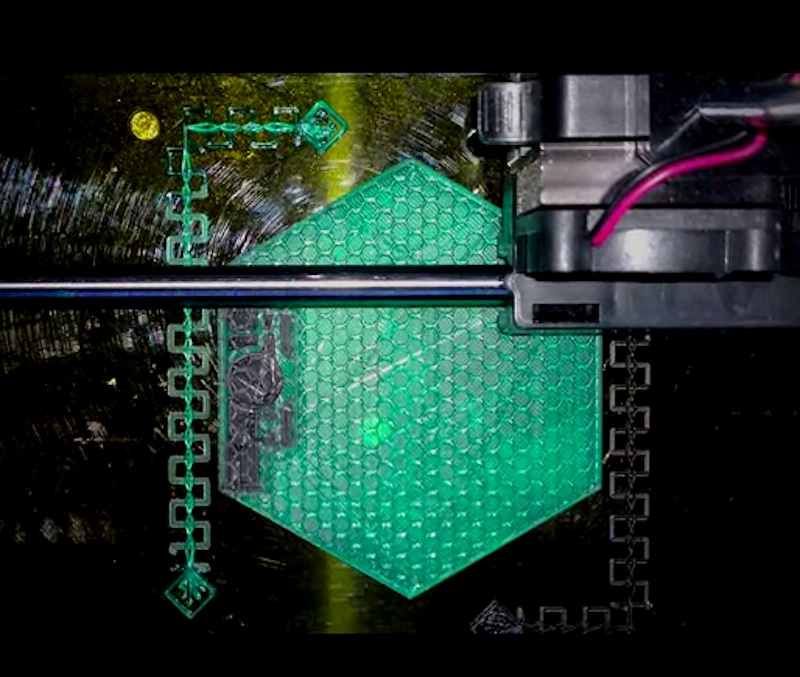

3D printing so far has focused on creating inert objects — toys, gears, even food.

But what if a 3D printer could print, say, circuit boards?

A startup believes it has invented the electrically conductive, extrudable material needed to make that happen.

“This is a breakthrough,” Mike Toutonghi told VentureBeat. He’s the CEO/founder of Functionalize, which is today launching a Kickstarter campaign to raise funds for production of the new filament, dubbed Functionalize F-Electric.

Toutonghi said that consumer-level PLA-capable 3D printers can use F-Electric to print circuits, wires, sensors, power connectors, and other electrical components. F-Electric’s impedance — a measurement of resistance to conductivity — is under 1 ohm per centimeter, while other conductive 3D-printable filaments are in the 1000- to 10,000-ohms/cm range.

Users, he envisioned, can now print most of the parts for, say, a smartphone, a drone, or a customized wearable. Toutonghi has tested the idea by printing a flashlight, for which he only needs to add a bulb and batteries.

Two birthdays

The story of this product’s development is bracketed by two birthdays.

At the dinner for his 50th birthday in fall of 2012, Toutonghi said he was talking to his son about an electromagnetic propulsion project for a school science fair. They’d need to make a circuit board, which would normally involve a lot of tricky soldering. Toutonghi, who’d just gotten a MakerBot Replicator II 3D printer, wondered if he could print the circuit board they needed.

When he started checking out materials, he said he was told it was impossible to have 3D-printed plastic with that kind of conductivity.

He did locate Carbomorph, the pioneering conductive 3D filament that had been invented by the University of Warwick and which, he said, became “an international sensation.” But “the conductivity was not enough to print circuits.”

So he built a lab in his home in the Czech Republic, where he was living to be near his children while working remotely as the CTO of Seattle-based software company Parallels. Eventually, the quest led him to quit his job and devote himself fulltime to this effort.

He invested countless hours trying to get material that could be extruded, could handle pressure and heat, and had sufficient conductivity.

Then came his son’s birthday, this past August.

That was the day, he said, when he got “the first plastic filament that printed beautifully and was conductive enough for circuits.” It is, he noted, “a thousand times more conductive than any 3D filament you can currently buy.”

“The disruption to be able to download a [technical] design and print any kind of wired device changes the world,” he told us. “This is the personal industrial revolution.”

You might be wondering about whether adding the filament means a lot of bare wires in your 3D thingy. Insulation can also be printed, but a user would need a two-headed, PLA-based printer, so that one head lays down the conductive filament and the other the insulation.

While Toutonghi declined to describe the patent-pending combination of materials he’s using, he did mention that the filament utilizes carbon nanotubes. A lab is currently being set up in Seattle, Toutonghi’s original hometown and the base for the new business.

An emerging tech space

The race for desktop electronic production is clearly on. A recent report in VentureBeat, for instance, described the release of the Voltara desktop circuit board printer.

“The Voltara system is a nice system if you are only interested in making more traditional circuit boards and want to buy a special device just for that,” Toutonghi told us. But its product is still just the circuit board.

“The idea behind our filament,” he said, “is that most people want to print anything and everything with their 3D printer. Now, instead of making a completely separate design and circuit board product, you print one complete thing that already includes the circuits, whether they’re in the shape of a board or not.”

The Kickstarter campaign — with an initial target of $100,000 — is intended to back production of the filament, with delivery in Q1 of next year. Products for Kickstarter backers include 3D-printed keychain flashlights and Makers Kits for 3D printing electrical projects.

VentureBeat's mission is to be a digital town square for technical decision-makers to gain knowledge about transformative enterprise technology and transact. Learn More