Presented by Nvidia

Industrial enterprises — the automotive, manufacturing and electronics organizations of the world — are in pursuit of digitalization, but are held back by mounting data silos and collaboration challenges. In response, a growing number of organizations across the world’s largest industries are unlocking interoperability across a complex ecosystem and throughout the manufacturing pipeline with the open-source Universal Scene Description (USD) standard, or OpenUSD, for an expanding variety of use cases.

“USD is the closest thing to a universal 3D standard there is today, but it’s currently only a de facto standard, not an internationally recognized standard like PDF or HTML,” says Guy Martin, director of open source and standards at Nvidia. “Industries like manufacturing, construction, architecture and engineering want and need to have open standards that they can count on.”

To achieve that, last year Pixar, Adobe, Apple, Autodesk and Nvidia launched the Alliance for OpenUSD to build true open standards for USD in many areas, including core specification, materials, geometry and more. And during the Siemens keynote at CES 2024 this past January, Cedrik Neike, CEO Siemens Digital Industries, announced the electronics behemoth had joined the Alliance, and was partnering with Nvidia to help create the next generation of persistent, intelligent, real-time AI-powered 3D universes.

Everything a company builds, from products and physical facilities to critical internal processes, can be digitally designed, simulated, operated and analyzed in real-time collaboration. 3D input can be accepted from any source and combined with an array of industrial data streams, like CAD data, live sensor data, asset data, documentation, maintenance records and more, all in one unified pipeline.

“OpenUSD’s core superpower is flexible data modeling,” explains Aaron Luk, director of product management at Nvidia and one of the founding developers of USD at Pixar. “And these models can be shared across different simulation tools and AIs, providing insights for all stakeholders of a given project.”

With USD, organizations are stripping away roadblocks, integrating teams, tools and technologies across the business, and developing new tools for the next era of industrial digitalization.

Seamless tool and team collaboration across enterprises

A unified standard means seamless, real-time virtual testing, experimentation, iteration and optimization across teams and functions. For instance, at electronics manufacturer Pegatron, one of the world’s largest manufacturers of smartphones and notebooks, different tasks utilize different tools, from factory layout and simulation of production lines to mechanical design of equipment and product design. These operations couldn’t be integrated because of the lack of common standards — until OpenUSD.

“In the age of AI, there is a need for standards that can describe more real-world information, digitizing physical information from the real world, and OpenUSD fills this gap,” says Andrew Hsiao, associate vice president at Pegatron. “It allows us to plan factories in 3D, collaborating in real time across roles and between applications to discover and mitigate issues before they ever start, speeding up the time-consuming and labor-intensive task of establishing automated equipment and production lines.”

Disparate technology and tools were also a roadblock at Taiwan-based IT giant Wistron Corporation.

“In the past, 3D assets created by each team for their projects were often limited to specific software or purposes,” says John Lu, manufacturing operations director at Wistron. “Now, by adopting USD for 3D asset management, we can maximize the assurance of asset quality and interoperability across diverse applications”

“One of the most significant advantages of using USD is its facilitation of team collaboration,” Lu adds. “Leveraging USD’s visualization capabilities and interoperability, we can compare different versions of plans, making it easier for decision-makers.”

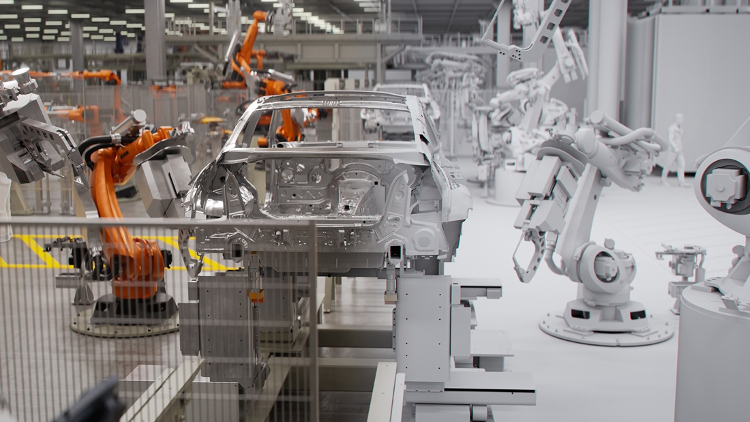

Seamless 3D data exchange is particularly important between simulation tools and the industrial metaverse platform used by Continental, one of Germany’s largest automotive parts manufacturing companies — and it’s possible with USD. The standard is crucial for allowing crosstool data exchange for use cases like production line planning and virtual Gemba walks.

“Using USD as an exchange standard provides us the possibility to utilize data across different tools and platforms. By this, we avoid time consuming conversions of CAD or other meta data and achieve a X-discipline ecosystem approach,” says Benjamin Huber, head of advanced automation & digitalization at Continental.

“The harmonized data streams between different engineering tools opens a variety of new use-cases and benefits. Our production planners, for example, can now collaborate easier across different functions and plants to create new manufacturing concepts. Complex change management and information loss is reduced which brings us another step closer to our vision of a full digital factory.”

Building new tools and integrations for the industrial revolution

ISVs and SIs are expanding the limits of OpenUSD and accelerating digitalization for the world’s industrial enterprises. For instance, ipolog GmbH, which produces developer planning software for production logistics and material provisioning, was inspired by BMW’s entirely digitalized smart factory to launch its spinoff startup SyncTwin GmbH.

“This introduction was a pivotal moment for us, unveiling the immense potential of a comprehensive digital factory twin built on OpenUSD,” says Michael Wagner, co-founder & CTO, SyncTwin. “This revelation was the key I had been searching for throughout my over two decades in the digital factory sector.”

SyncTwin is now developing native tools and solutions with the Nvidia Omniverse, the platform for connecting and developing OpenUSD applications, particularly within its specialty area of manufacturing planning and execution. The company’s integrations are designed to help dismantle data silos and enhance collaboration across factory domains, addressing distinct SME challenges and offering solutions for container transport simulation, worker scheduling, optimizing factory layout space utilization and more.

FlexSim, which was acquired by Autodesk to add factory simulation and operational efficiency analysis to its factory design tools, used Nvidia APIs to develop an Omniverse connector that enables clients to more easily share simulation model data, including both geometric and object metadata, all using OpenUSD.

“Manufacturing and warehousing facilities often rely on complex digital models to inform production decisions, but that data needs to be portable,” says Phil BoBo, senior manager, FlexSim software development, at Autodesk. “In the manufacturing industry, we have clients now using OpenUSD to import data into their simulation models more easily with less information lost using translation steps between data sources.”

Rockwell Automation developed a USD connection for users of their Emulate3D virtual commissioning software to dynamically stream their simulations into the tools and applications they build with the Omniverse platform.

“From the inception of Omniverse we realised its potential to create a digital twin ‘forum’ where all stakeholders in a manufacturing project could collaborate,” says John Pritchard, business manager – Emulate3D at Rockwell Automation. “Omniverse has increased the scale of a system which can be visualized at one time. Multiple disciplines of digital models can be combined in one place and viewed in tandem. Higher fidelity models can be split across multiple separate simulations and be visualised simultaneously in applications and services developed with Omniverse.”

Making those virtual worlds as exactingly precise as possible is critical for industrial applications. Hexagon, a global leader in digital reality solutions, collaborated with Nvidia and the Alliance for OpenUSD right out of the gate to build Omniverse integrations from their HxDR digital reality and Nexus manufacturing platforms. The goal is to offer advanced capabilities in reality capture, digital twins, AI, simulation and visualization.

“Hexagon’s reality capture data, describing everything from car parts to buildings to cities, will augment Omniverse-powered applications, allowing users to update their simulation-ready virtual worlds to reflect the most current reality,” explains Frank Suykens, senior vice president, visual computing at Hexagon. “This year will be one of exponential growth for OpenUSD applications for industrial digitalization.”

Meanwhile, SoftServe is focused on the future of collaboration, with the goal of enabling multiple designers, engineers — even different businesses — to collaborate in a virtual world.

“Imagine a marketplace where various vendors can offer digital twins of their equipment to address real automation challenges through simulations before shipping the actual asset,” says Taras Bachynskyi, VP of technology at SoftServe. “Or collaborative product design in the metaverse, where every change in the body design, electrical or mechanical parts of the product will be automatically simulated, validated and become visible to all involved parties in real time.”

These innovations are just a preview into how enterprises are using OpenUSD to accelerate time-to-market and significantly reduce cost of product design, manufacturing engineering, production planning and more. Learn about how these companies and others, including Ascon Systems, Cesium, IMK and Kinetic Vision, are innovating with OpenUSD during OpenUSD Day on Tuesday, March 19th at Nvidia GTC 2024.

Sponsored articles are content produced by a company that is either paying for the post or has a business relationship with VentureBeat, and they’re always clearly marked. For more information, contact